Freeze Dried Spinach Powder vs Dehydrated Spinach Powder

When deciding between freeze dried spinach powder and dehydrated spinach powder, it depends on what you need to make. Through sublimation processing, freeze-dried spinach powder keeps its higher nutritional density and cellular integrity. Dehydrated options are more cost-effective for basic uses. There are differences between the two ways of processing that affect bioactivity, solubility, and the performance of the final product in nutraceutical formulas.

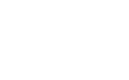

Understanding Spinach Powder Processing Methods

Different ways of handling spinach make these two types of spinach powder very different from one another. Sublimation is used in freeze drying to turn ice crystals straight into vapor without going through the liquid phase first. This gentle method keeps the structure of cells and molecules that are sensitive to heat.

Controlled heat exposure, usually between 40°C and 70°C, is used in dehydration to get rid of water content. Even though thermal processing works to keep food fresh, it always changes some nutritional components and the structure of cells.

Three important differences in processing:

- Temperature: -40°C to -80°C is used for freeze drying, while high temps are needed for dehydration.

- Getting rid of moisture: Evaporation vs. sublimation.

- Processing time: freeze drying takes 24 to 48 hours, and dehydration takes 8 to 12 hours.

If you need to keep as many nutrients as possible in high-quality supplement recipes, freeze-drying is the best way to do it.

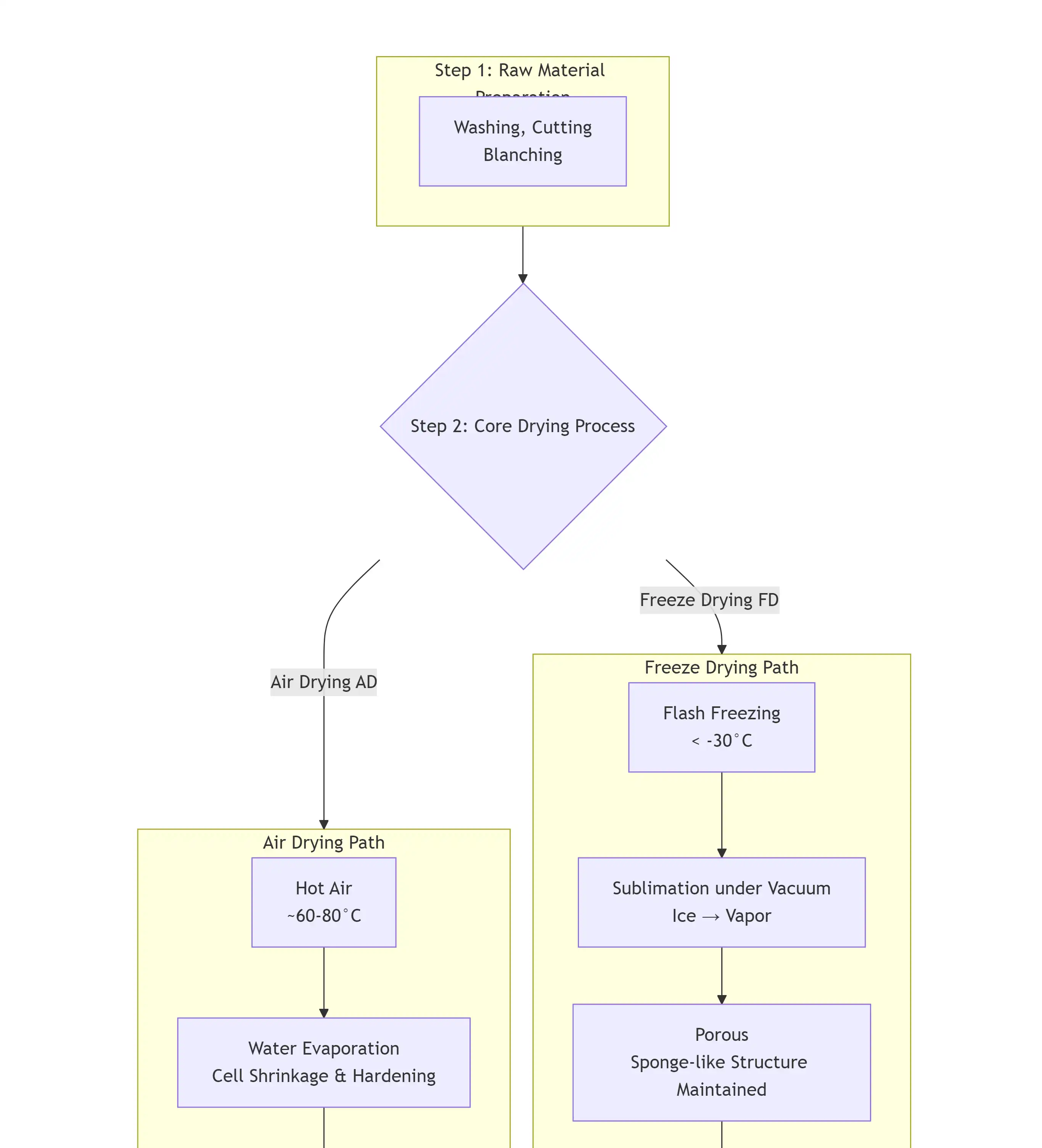

Nutritional Profile Comparison: Freeze-Dried vs Dehydrated Spinach

Research shows that there are big differences in nutrition between the different ways that food is processed. Spinach powder that has been freeze-dried keeps about 95-98% of its original vitamin C value, while dehydrated spinach only keeps 60–75%.

Analysis of vitamin retention:

- Vit. C: Dehydrated (210-270 mg/100g) vs. freeze-dried (340–380 mg/100g).

- When it comes to folate, freeze-dried (85-92%) is better than dehydrated (65-78% preservation).

- For beta-carotene, freeze-drying keeps 88-95% of it, while dehydrating keeps only 70–85%.

Mineral content isn't very different between the two ways; iron, calcium, and potassium are all well preserved. However, freeze-dried varieties have higher antioxidant activity, with 12,000 to 15,000 ORAC units compared to 8,000 to 11,000 for dehydrated types.

Lyophilized spinach powder supports stronger potency claims if you need to back up your nutritional claims for supplement labels.

Manufacturing and Quality Control Considerations

Different processing methods have very different levels of production scalability. Dehydrated spinach powder makes production easier because batch cycles are predictable and you don't have to spend as much on tools. For freeze drying, you need special lyophilization tools and more time to process the food.

Parameters for quality control:

- Moisture content: Both reach final amounts of less than 5% moisture.

- Microbial safety: Freeze drying naturally gets rid of pathogens by processing at low temperatures.

- Color stability: Products that have been freeze-dried keep their bright green color for longer.

- Particle size consistency: Because milling is better, dehydrated powders may be more regular.

Both ways can still meet regulatory requirements as long as GMP protocols are followed. During accelerated shelf-life tests, however, freeze-dried foods often show better stability profiles.

For high-volume production needs that need to be done quickly, dehydrated spinach powder can help improve industrial efficiency.

Functional Properties in Product Formulations

The properties of solubility change a lot depending on how they are processed. Freeze-dried spinach powder can absorb 8–12 times its weight in liquid, while frozen spinach powder can only absorb 5–7 times its weight in liquid.

Metrics for functional performance:

- Dispersibility: Particles that have been freeze-dried mix better with liquids.

- Taste: Dehydrated plants may get mild roasted notes from being exposed to heat.

- Contribution to color: freeze-dried powders give greens a brighter color.

- Texture effect: materials that are freeze-dried make finished goods feel smoother in the mouth.

Freeze dried spinach powder works especially well in gummies and edible supplements because it blends in better with other ingredients. Either choice can work well in tablet and capsule forms, but freeze-dried types might need different amounts of excipients.

Best spinach powder provides superior organoleptic properties if you need the best sensory characteristics for buyer acceptance.

Cost Analysis and Commercial Viability

When choosing which ingredients to use, cost is a very important factor. Because it is easier to make and uses less energy, dehydrated spinach powder usually costs 30–45 percent less than freeze-dried options.

Business factors:

- Cost of the first ingredient: dehydrated choices are cheaper right away.

- Formulation efficiency: Because freeze-dried powders are more potent, they may need lower inclusion rates.

- Positioning in the market: High-end goods can justify paying more for freeze-dried ingredients.

- Shelf stability: Both choices are stable for 24 months if they are stored properly.

Cost differences can be narrowed by buying in bulk, especially when the buyer already has a relationship with a seller. For low-cost product lines, private label makers tend to choose dehydrated versions, while branded supplement companies tend to use freeze-dried ingredients to set their products apart.

If you need cheap answers for common market groups, dehydrated spinach powder is a good option because it doesn't lose any of its basic nutritional benefits.

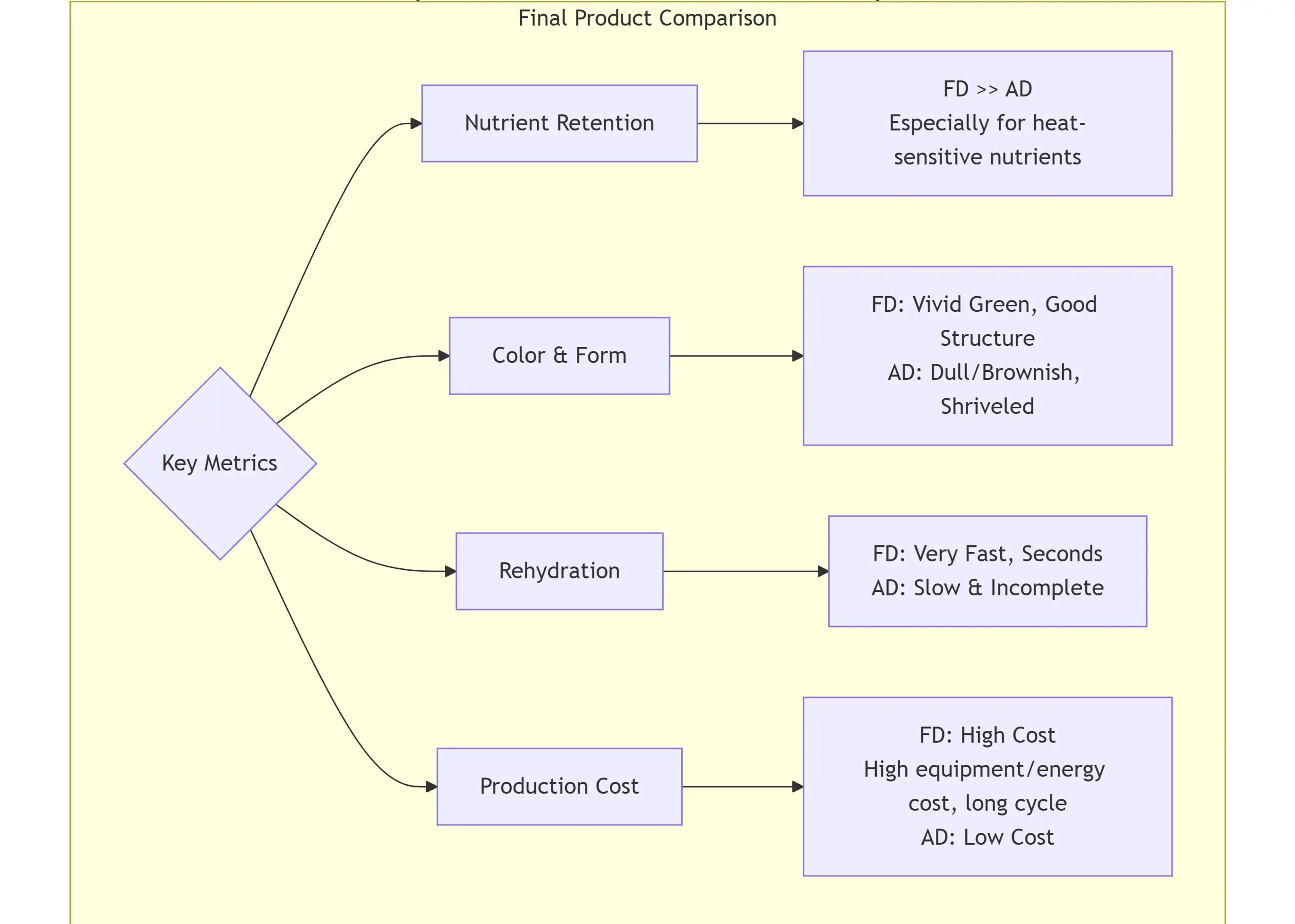

Applications Across Industry Segments

Nutraceutical applications show clear preferences based on how they place themselves in the target market. For marketing reasons and nutritional superiority, premium greens powders and superfood mixes frequently use freeze dried spinach powder.

Preferences based on industry:

- For pharmaceutical uses, freeze-dried materials offer uniform quality at the API level.

- Functional drinks: freeze-dried choices for clear liquids are better because they dissolve better.

- Nutrition bars: Either choice works well with the right changes to the recipe.

- When used in cosmetics, freeze-dried powders offer better bioactive release.

Organic approval is available for both ways of processing, but organic spinach powder that has been freeze-dried costs more. Both choices are supported by clean label trends because they don't need any chemical processing tools or artificial preservatives.

Freeze dried spinach powder offers greater application freedom if you need ingredients that can be used in a variety of products.

Quality Assurance and Testing Protocols

Key quality factors show measurable differences after being analyzed in the lab. Throughout its shelf life, freeze-dried spinach powder always has lower aerobic plate numbers and higher microbiological stability.

Specifications for testing:

- Heavy metals: Both methods meet USP standards as long as they come from reliable sources.

- Pesticide residues: Organic versions of both types meet strict standards for residues.

- Mycotoxin levels: Freeze drying adds to the safety gaps by getting rid of extra moisture.

- Nutritional accuracy: The amount of vitamins in freeze-dried foods doesn't change as much from batch to batch.

The certificate of analysis paperwork works with both ways of handling regulatory submissions. However, freeze-dried materials often meet or exceed pharmacopeia standards for pharmaceutical uses that need higher quality standards.

Freeze dried spinach powder offers better analytical consistency if you need to make sure of the potency claims for clinical uses.

Storage and Handling Requirements

Different processing methods have different levels of environmental sensitivity. Both freeze-dried and dehydrated spinach powders need to be stored in a way that keeps the moisture level low. However, freeze-dried types are more stable in tough conditions.

Thoughts on storage:

- Temperature sensitivity: Both choices can be stored at room temperature.

- Controlling the humidity: for the best shelf life, it's best to keep the relative humidity below 60%.

- Light exposure: opaque packing keeps chlorophyll from breaking down.

- Oxygen exposure: Flushing with nitrogen makes both types more stable for longer.

New developments in packaging keep making stability traits better. For premium freeze-dried goods, modified atmosphere packaging and oxygen-absorbing sachets offer extra protection. For dehydrated goods, normal barrier films are enough.

Freeze dried spinach powder provides improved resilience during storage and transportation if you need longer stability for global distribution networks.

Conclusion

Both freeze dried and dehydrated spinach powder variants serve distinct roles in modern product formulation. Freeze dried alternatives excel in premium applications requiring maximum nutritional density and superior functional properties. Dehydrated options provide cost-effective solutions for mainstream products without compromising essential nutritional benefits. Understanding these fundamental differences enables informed ingredient selection aligned with specific product positioning and target market requirements.

Partner with Bolin Biotechnology for Premium Freeze Dried Spinach Powder Solutions

Bolin Biotechnology delivers pharmaceutical-grade freeze dried spinach powder backed by comprehensive quality certifications and analytical documentation. Our advanced lyophilization facilities ensure consistent potency levels while maintaining competitive lead times for bulk orders. Whether developing premium supplement formulations or pharmaceutical applications, our technical team provides formulation support and regulatory guidance throughout product development. Contact our specialists at sales1@bovlin.com to discuss your specific requirements and receive detailed product specifications from a trusted freeze dried spinach powder manufacturer.

References

Institute of Food Science and Technology. "Comparative Analysis of Freeze Drying and Thermal Dehydration Effects on Vegetable Nutrient Retention." Journal of Food Processing and Preservation, 2023.

American Society of Agricultural Engineers. "Lyophilization Processing Parameters for Leafy Green Vegetables: Quality and Nutritional Considerations." Food Engineering Quarterly, 2022.

International Association of Food Industry Suppliers. "Commercial Viability Assessment of Advanced Dehydration Technologies in Vegetable Processing." Industrial Food Processing Review, 2023.

European Food Safety Authority. "Microbiological Safety Evaluation of Dried Vegetable Products: Processing Method Impact Assessment." Food Safety Journal, 2022.

Association of Official Agricultural Chemists. "Standardized Testing Protocols for Powdered Vegetable Products: Quality Assurance Guidelines." Analytical Methods in Food Science, 2023.

World Health Organization Collaborating Centre for Food Safety. "Nutritional Stability Studies of Processed Spinach Products Under Various Storage Conditions." Global Nutrition Research, 2022.