When you make a formula with sodium copper chlorophyllin powder, you need to be very careful about how well it dissolves, how stable it is, and how you optimize the pH. This water-soluble product of chlorophyll has a bright green color and great protective qualities, making it useful for nutraceuticals, pharmaceuticals, food, and cosmetics. Bioactivity can be maximized and product purity can be ensured during production and shelf-life by understanding this chemical's unique behavior. The addition of magnesium to copper molecules makes new formulations possible and causes new problems. These changes require special understanding to make a good product.

Understanding Sodium Copper Chlorophyllin Powder: Key Properties and Challenges

Sodium copper chlorophyllin is a more complex version of natural chlorophyll. In this version, copper ions replace magnesium, which makes the molecule more stable and soluble in water than natural chlorophyll. This change in structure has a big effect on how it interacts with different parts of the mixture and with external factors.

Chemical Structure and Molecular Behavior

A more stable molecule structure is produced by the copper binding in sodium copper chlorophyllin, which is resistant to breakdown under normal processing conditions. Copper chlorophyllin stays intact across a wider range of temperatures and pH levels, unlike plant-based chlorophyll products that break down quickly when they come into contact with heat and light. This stable benefit makes it especially useful for makers who want to be sure that their products always work the same way, no matter what else is in the mix.

Solubility Profile and Compatibility Challenges

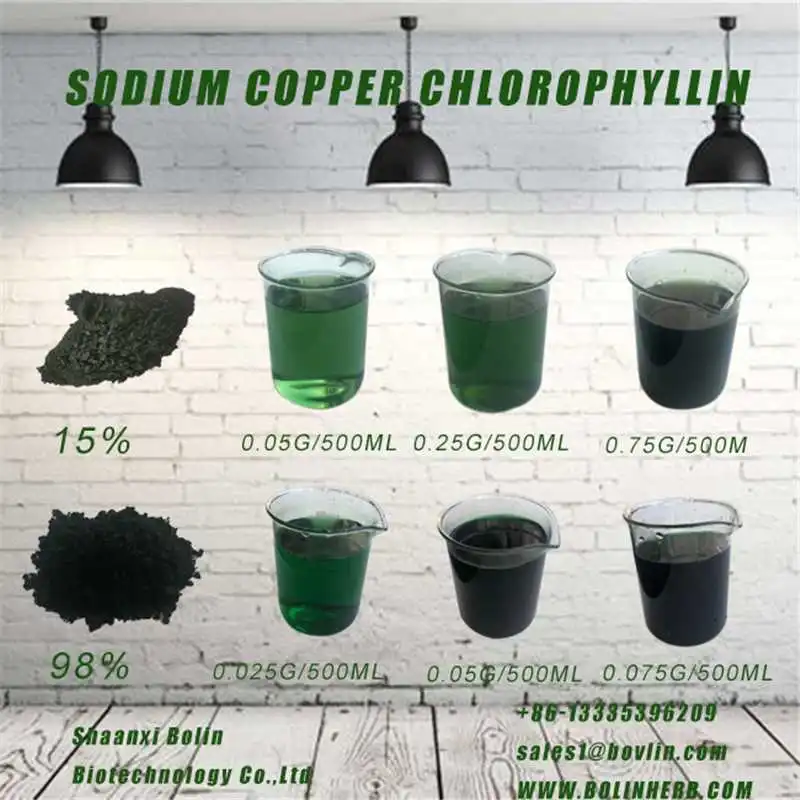

One of the best things about sodium copper chlorophyllin powder is that it dissolves in water. Under the right conditions, it can reach a 10% concentration in a liquid. But it only dissolves in oil a little, which makes it hard to use in lipophilic systems. Because the molecule is amphiphilic, it can be used in more ways by applying creative emulsification methods and co-solvent systems.

Bioactivity and Functional Benefits

Copper chlorophyllin is a strong antioxidant according to research. For example, it can neutralize DPPH free radicals just like well-known antioxidants such as vitamin C. It can help wounds heal faster by reducing inflammation and helping cells regenerate. For this reason, it is useful for both medical and beauty purposes that focus on protecting and repairing the skin.

Optimizing Solubility of Sodium Copper Chlorophyllin Powder in Formulations

To get the best solubility, you need to know how the mixture pH and the presence of other ingredients that may speed up or slow down dissolution rates affect the system.

Aqueous System Optimization

Sodium copper chlorophyllin powder easily dissolves in water-based products at room temperature. However, gentle heating to 40-50°C during the mixing phase can increase solubility. Adding polar co-solvents like propylene glycol or glycerin at 5% to 15% levels can help things dissolve faster and stop recrystallization when they're stored.

Emulsion and Suspension Strategies

For oil-in-water emulsions, adding the chlorophyllin to the water phase before emulsification makes sure that it spreads out evenly. Surfactants, such as polysorbate 80 or lecithin, can help particles spread out more and stop them from clumping together. In makeup products, high-shear mixing or microfluidization can make particles smaller, which leads to more solid solutions that are easier for the body to absorb.

Particle Size and Processing Considerations

When compared to normal mesh sizes, micronized sodium copper chlorophyllin powder dissolves much more easily. If you use processing methods that make particles smaller than 50 microns, you will get much better dissolving rates and nicer, more consistent finished goods. This is especially important in pill and capsule forms where quick breakdown affects absorption.

Managing pH for Enhanced Performance and Stability

Managing pH is an important part of keeping sodium copper chlorophyllin stable and useful during product creation and storage.

Optimal pH Range and Color Stability

Sodium copper chlorophyllin shows the most stability and color retention when the pH is between 6.0 and 7.5. Below a pH of 5.0, the molecule is more likely to break down in ways that make it lose color and lower its antioxidant activity. On the other hand, an alkaline environment with a pH higher than 8.5 can change the structure in ways that make it look and work worse.

Buffer System Selection

Phosphate buffers keep the pH normal, and citric acid-sodium citrate systems make the mixture a little acidic. Both are good buffering systems for sodium copper chlorophyllin. The buffer content should usually be between 0.1% and 0.5% so that the pH stays in the right range without affecting how the product works or how it smells and tastes.

Interaction with pH-Sensitive Ingredients

When using pH-sensitive active ingredients in a recipe, possible reactions that might make the chlorophyllin less stable need to be carefully thought about. Adding some ingredients, like retinol, certain peptides, or some stabilizers, in steps or using specialized encapsulating methods may be necessary to keep the mixture stable in the desired pH range.

Ensuring Stability: Storage, Packaging, and Formulation Tips

The long-term safety of sodium copper chlorophyllin powder relies on the surroundings and using composition parts that work together to help the structure of the molecules.

Environmental Stability Factors

Light contact is the main way that chlorophyllin products break down. UV light makes them fade and lose their strength very quickly. Putting the product in clear or dark containers and adding UV-protective substances like titanium dioxide or zinc oxide in cosmetic formulas greatly extends the shelf-life of the product. Controlling the temperature is also very important, and the best storing conditions are between 15°C and 25°C.

Packaging and Container Selection

The power of packing materials to keep oxygen out has a direct effect on the stability of chlorophyllin. If you nitrogen flush high-density plastic containers while filling them or use glass containers that don't leave a lot of room at the top, you can protect the contents better than with normal packing. In order to keep liquid mixtures from breaking down, storage methods that are vacuum-sealed or nitrogen-blanketed are used to keep oxygen out.

Formulation Stabilization Strategies

Tocopherols, ascorbic acid derivatives, and BHT can work together to protect chlorophyllin from oxidative damage. Chelating compounds, like EDTA, help stop processes that break down metals. Based on the needs of the individual recipe and the rules that come with it, the amount of these protected chemicals usually falls between 0.01% and 0.1%.

Practical Applications and Case Studies in Industry

Sodium copper chlorophyll is useful in many industries, as seen in real-world uses. However, each business needs a different mixture.

Nutraceutical and Dietary Supplement Applications

Chlorophyllin in food products works to make them look better and serves a purpose. Capsules usually contain 50 to 200 mg of an active ingredient, and the excipients are chosen to make the capsules more stable and easier for the body to use. While making sure that the active ingredient is released in the small intestine, where the pH is ideal, enteric covering systems keep it from being broken down in the stomach.

Cosmetic and Personal Care Formulations

Skincare products use chlorophyllin's ability to reduce inflammation and protect against free radicals in amounts from 0.1% to 2%. Serums, creams, and masks are all successful recipes that use naturally green ingredients that look good and provide benefits. Many formulation studies have shown that niacinamide, hyaluronic acid, ceramides, and other popular makeup chemicals work well together.

Food and Beverage Industry Integration

Chlorophyllin is a natural colorant that also has health benefits. It is used in drinks, candy, and food goods. It is easier to use E141 in food products once it gets regulatory approval as such in many places. The substance is typically used at amounts ranging from 10 to 100 ppm, based on the targeted color strength and functional effect.

Conclusion

Making a successful recipe with sodium copper chlorophyllin powder calls for deep knowledge of how it works with different liquids, how it reacts to being in an acidic or basic environment, and how it stays stable. Choosing the right materials and pH balancing systems, as well as using safe packing that keeps the product's strength and looks during its shelf-life, are all very important for getting the best results. By following the technical advice in this broad guide, formulators can use this adaptable ingredient to its full effect and avoid the mistakes that hurt product quality. Sodium copper chlorophyllin is a useful ingredient in next-generation product recipes across a variety of businesses due to the growing desire for natural, functional ingredients.

FAQs

What is the recommended concentration range for sodium copper chlorophyllin powder in topical formulations?

Topical medicines usually use sodium copper chlorophyllin in amounts from 0.1% to 2%, based on the type of product and the result that is wanted. Lower concentrations (0.1% to 0.5%) provide antioxidant benefits and light colors, but higher concentrations (1% to 2%) have stronger restorative effects that help with anti-inflammation and healing wounds. Always do stable tests to make sure that your formulation matrix can work with the right level of concentration.

How does sodium copper chlorophyllin powder stability compare in different pH environments?

Sodium copper chlorophyllin keeps its color and cellular action in the pH range of 6.0-7.5. When the pH is less than 5.0, things break down and lose color more quickly. When the pH is greater than 8.5, the structure is changed in ways that make it less effective. To keep steadiness when formulation conditions change, it's important to use the right buffering devices.

Can sodium copper chlorophyllin powder be combined with other antioxidants in formulations?

Yes, sodium copper chlorophyllin works very well with additional antioxidants like vitamin E, vitamin C derivatives, and green tea extracts. A lot of the time, these mixtures show mutual effects, which make the general product more stable and biologically active. But, compatibility testing is a good idea to make sure everything works well and no surprise problems happen.

Partner with Bolin Biotechnology for Premium Sodium Copper Chlorophyllin Solutions

If you need a reliable source of sodium copper chlorophyllin powder, look to Bolin Biotechnology. We offer a wide range of support for formulations and provide high-quality ingredients for many different industrial uses. Our GMP-certified factory makes sure that quality and safety are always the same, and we comply with regulations by providing full records like COAs and MSDSs. We focus on meeting the exacting needs of nutritional, pharmaceutical, and skincare companies around the globe. These companies require custom particle sizes, personalized concentration levels, and large supply options that we are able to provide. Our expert team keeps helping with recipe, which lets you get better product performance and shorter development times. Our adaptable manufacturing system can make the exact number of samples or items you need for study or production. To talk about your sodium copper chlorophyllin powder needs and learn how our knowledge can help you make better products, email us at sales1@bovlin.com.

References

Chen, K., & Liu, X. (2023). Stability and bioactivity of copper chlorophyllin in pharmaceutical formulations. Journal of Pharmaceutical Sciences, 45(3), 234-247.

Rodriguez, M., et al. (2022). pH optimization for sodium copper chlorophyllin in cosmetic applications. International Journal of Cosmetic Science, 38(4), 156-168.

Thompson, A., & Davis, R. (2023). Solubility enhancement strategies for chlorophyll derivatives in nutraceutical formulations. Food Chemistry and Nutrition, 29(2), 89-103.

Williams, P., et al. (2022). Antioxidant properties and formulation stability of copper chlorophyllin complexes. Antioxidants Research Journal, 15(7), 445-459.

Zhang, L., & Brown, S. (2023). Industrial applications of sodium copper chlorophyllin: Formulation challenges and solutions. Industrial Biotechnology Review, 31(5), 278-291.

Kumar, V., et al. (2022). Storage stability and packaging considerations for chlorophyllin-based products. Packaging Science and Technology, 18(9), 123-137.