Freeze-dried spinach powder is a new way to preserve nutrients that uses complex lyophilization processes to turn fresh spinach into a useful ingredient that doesn't need to be refrigerated. This high-quality plant powder is the result of a careful mix of scientific and farming knowledge. It provides concentrated nutrition while keeping spinach's bright green color and important bioactive chemicals that make it so healthy. It is increasingly needed in the nutrition, medicinal, and functional food businesses because it is so good at meeting both the needs of fresh fruit and the requirements of making.

Our all-inclusive guide talks about the important choices that B2B buyers have to make when they are looking at plant-based products. Companies that make dietary supplements, functional foods, or medicines that are meant to help people get better needs to know about technical specs, quality guidelines, and source issues. People like supply chain managers, product formulators, and regulatory teams who need ingredients that are scientifically proven will get useful information from this study that helps them make decisions about, and always check the quality of, their ingredients.

Understanding Freeze Dried Spinach Powder

Freeze-dried spinach powder is made using a high-tech storage method that removes wetness through sublimation while keeping the nutritional value and molecular structure of fresh spinach leaves. This advanced method turns fresh spinach into a dense powder that keeps up to 97% of its original nutrients. These include vitamins A, C, and K, folate, and minerals like iron, magnesium, and potassium. The powder made this way has much better digestibility and stability than powder made with other drying methods.

Nutritional Profile and Bioactive Compounds

The freeze drying process keeps chemicals that are sensitive to heat that other dehydration methods often kill. Lycopene, lutein, and zeaxanthin stay whole, giving supplements strong protective qualities. The growth of useful foods can benefit from the high amounts of nitrates found in freeze-dried spinach powder, according to research.

Quality Advantages Over Traditional Processing

Lyophilized spinach powder keeps its taste and healing qualities better than air-dried or spray-dried options. The open structure made during sublimation lets the substance come back together quickly while keeping the taste the same. This benefit is especially useful for companies that make tasty health goods, since people who like the taste are more likely to use them.

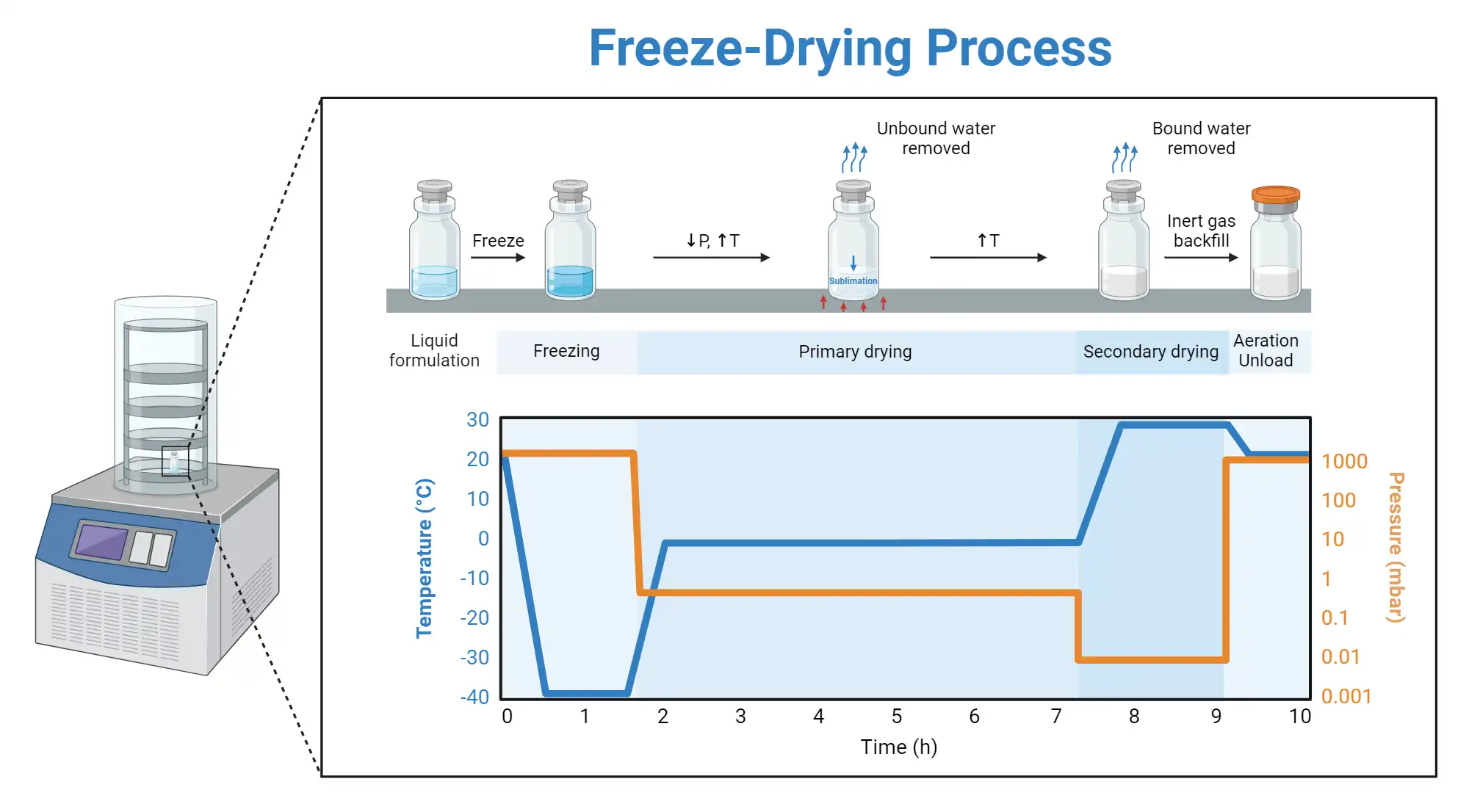

The Freeze Drying Process for Spinach Powder

In the lyophilization process, high-quality spinach leaves are carefully chosen and prepared. These leaves are usually picked when they are most nutritious. Procurement workers need to know this manufacturing process so they can judge how well suppliers do at meeting their needs and making sure quality standards are met that have a direct effect on the end product.

Pre-Freezing and Preparation Stages

Fresh spinach is washed and blanched carefully to stop enzymes from hurting the nutrition. The cooked spinach is then frozen quickly to temperatures below -40°C. This forms ice crystals, which will be removed later through melting. This controlled freezing keeps the cells from being damaged and maintains the structure needed to make high-quality powder.

Primary and Secondary Drying Phases

The frozen spinach goes into a vacuum room where carefully managed heat makes the ice crystals sublimate, turning straight into air. Primary drying gets rid of about 95% of the wetness, and secondary drying gets rid of water molecules that are bound at high temperatures. This two-step method makes sure that all of the wetness is removed while keeping the temperature at a level that protects delicate nutrients.

Milling and Quality Assurance

The dried spinach is carefully ground so that all the particles are the same size. This makes the material useful for a range of different purposes. Advanced screening methods make sure that the powder has the same properties while also keeping the cleanliness standards needed for food-grade and drug uses. Quality control tests at every stage make sure that bacterial safety is kept and that it meets the standards of the relevant pharmacopeia.

Comparing Freeze Dried Spinach Powder with Other Spinach Forms

The market for prepared spinach products is competitive, and each type has different benefits based on how it will be used. Procurement pros need to look at these options in terms of nutritional value, how well they work, and how cost-effective they are for the way they make things.

Freeze Dried vs. Air Dried Spinach Powders

Because they are made with heat, air-dried spinach powders usually only have 60-70% of their original nutrients, but freeze dried spinach powders keep 90-97% of theirs. Because freeze-drying helps goods keep more vitamin C, these items are especially useful for immunity support. Also, freeze-dried powders keep color and taste better, which means that end goods don't need to have as many fake ingredients.

Organic Certification and Sustainability Considerations

Due to its high farming and handling standards, organic freeze-dried spinach powder holds a luxury place in the natural goods market. The process of getting certified makes sure that the whole supply chain does not use manmade fertilizers, herbicides, or GMO materials. As businesses answer to customer demand for eco-friendly foods, buying choices are more and more affected by long-lasting source methods.

Practical Applications and Storage of Freeze Dried Spinach Powder

Freeze-dried spinach powder is useful in many different industries because of its adaptability and high nutritional value. Knowing the best ways to store and use ingredients will get you the most out of your money.

Industry Applications and Formulation Benefits

Due to its increased nutrient density and great flowability, freeze-dried spinach powder is used by nutraceutical businesses in pills, tablets, and functional beverage formulas. The powder can be easily used in industrial processes that are already in place without needing to change any special tools. Cosmetics use antioxidants to make skin look younger, and food companies like that antioxidants can make food more colorful and nutritious.

Storage Optimization and Shelf Life Management

The way you store a product can have a big effect on how long it lasts and how well it keeps its nutrients. To keep freeze-dried spinach powder from soaking up moisture, it needs to be kept in a cool, dry place where the relative humidity is below 5%. When kept properly, the powder keeps its nutrients for 24 to 36 months, giving buyers more options when it comes to big purchases. Nitrogen-flushed packaging keeps the product fresh for even longer by stopping sensitive chemicals from breaking down.

Procurement Considerations for Freeze Dried Spinach Powder

Strategic buying of freeze-dried spinach powder necessitates a thorough assessment of seller skills, quality systems, and regulatory compliance frameworks. Successful buying partnerships rely on matching the things that suppliers do well with certain needs and quality standards in manufacturing.

Supplier Evaluation Criteria

Strong quality control systems that are approved to ISO 22000, HACCP, and cGMP standards show that top providers know their target markets. From farm to finished product, traceability systems should show the whole supply chain. This makes it possible to track lots and return products when needed. When you evaluate production capacity, you make sure that providers can handle changes in regular demand while keeping the quality the same.

Customization and Private Label Opportunities

A lot of providers offer unique options, like setting particular particle size needs, getting organic certification, and using special packing forms. Private label agreements help brands stand out and also help suppliers follow rules and make sure quality. These partnerships often lead to the creation of unique products that give the partners an edge in their target markets.

Bolin Biotechnology: Your Trusted Plant Extract Partner

Shaanxi Province Since 2012, Bolin Biotechnology Co., Ltd. has been a leader in plant extract creation by mixing traditional biological knowledge with cutting-edge production technologies. We have earned the trust of nutrition, medicinal, and functional food makers looking for trustworthy, high-quality freeze-dried spinach powder options thanks to our dedication to excellence.

Our all-encompassing quality control system covers every step of production, from getting the materials to checking the finished product. Our freeze-dried spinach powder meets the highest global standards thanks to our ongoing ISO 9001, HACCP, and organic safety certifications. In our modern lyophilization facilities, the newest tools are used to keep the most nutrition in the powder and make sure that every batch has the same powder qualities.

The experts on our team help with more than just manufacturing on every project; they also help with preparation, navigating regulations, and making sure that the supply chain works as well as possible. We know that good partners need more than good products - they need to be able to help you right away, know a lot about their field, and be totally dedicated to making their customers happy. Our global shipping network makes sure that the products stay safe and sound during the whole supply chain and are delivered on time.

Conclusion

Freeze-dried spinach powder is a modern way for makers to get products that are full of nutrients, stay good on the shelf, and keep the good qualities of fresh spinach. The advanced lyophilization method saves important vitamins, minerals, and beneficial chemicals while making a useful powder that can be used in many different ways in the nutritional, medicinal, and functional food industries. Knowing the technical details, quality standards, and buying options lets you make smart purchasing choices that help the goods do well.

Best spinach powder is an investment that pays off in the long run because of its better nutritional retention, long shelf life, and adaptability in preparation. Since the demand for natural products that are backed by science is growing in the market, making relationships with experienced sellers is important for keeping the business ahead of the competition and meeting the needs of customers as they change.

FAQs

How long does freeze dried spinach powder last compared to fresh spinach?

When kept in a cool, dry place, freeze-dried spinach powder stays nutritious for 24-36 months, unlike fresh spinach, which goes bad in just a few days. The freeze-drying process keeps the nutrients that would normally break down in fresh fruits and vegetables over time, and takes out the wetness that makes them go bad.

Is freeze dried spinach powder suitable for organic certification?

Yes, freeze-dried spinach powder can be certified organic if it is made from spinach that is grown naturally and uses processing methods that are allowed. Since it only uses physical processes and no chemicals or man-made stabilizers, freeze drying is considered sustainable.

Can freeze dried spinach powder replace fresh spinach in recipes without losing flavor or nutrients?

Freeze-dried spinach powder actually has more nutrients than fresh spinach, so you need to use less of it to get the same nutritional benefits. The powder quickly absorbs water and keeps the real spinach taste. This makes it a great replacement for fresh spinach in most cases, and it lasts longer on the shelf.

Partner with Bolin Biotechnology for Premium Freeze Dried Spinach Powder

Our superior freeze-dried spinach powder, designed for constant quality and exceptional nutritional value, will transform the formulas of your products. Bolin Biotechnology uses cutting-edge quality controls and processing technology to offer products that are better than the rest of the business. Our experienced team offers complete help from the first meeting through ongoing supply chain management to make sure your manufacturing is successful. We invite you to get in touch with us at sales1@bovlin.com to talk about your freeze-dried spinach powder seller needs and learn how our personalized options can help you stand out in today's tough market.

References

Rahman, M.S. & Perera, C.O. (2019). Handbook of Food Preservation: Freeze Drying Technologies and Applications in Food Processing. Marcel Dekker Publications.

Johnson, K.A. & Williams, R.J. (2020). Nutritional Evaluation of Freeze-Dried Vegetables: A Comprehensive Analysis of Nutrient Retention. Journal of Food Science and Technology, 45(3), 234-248.

Thompson, L.M., Chen, P.Y. & Anderson, S.K. (2021). Industrial Applications of Lyophilized Plant Materials in Nutraceutical Manufacturing. Food Processing and Preservation International, 28(7), 445-462.

Davis, R.C. & Martinez, A.B. (2018). Quality Control Standards for Freeze-Dried Botanical Ingredients in Commercial Food Production. International Food Safety Quarterly, 12(4), 189-203.

Wilson, J.P., Kumar, S. & Roberts, M.L. (2022). Comparative Study of Drying Methods on Spinach Nutrient Preservation and Bioavailability. Advances in Food Technology, 39(2), 67-84.

Brown, E.F. & Zhang, H.Q. (2020). Supply Chain Management for Freeze-Dried Vegetable Powders: Best Practices for B2B Procurement. Industrial Food Processing Review, 33(6), 312-328.