How Is Hydrolyzed Corn Protein Produced for Food Applications?

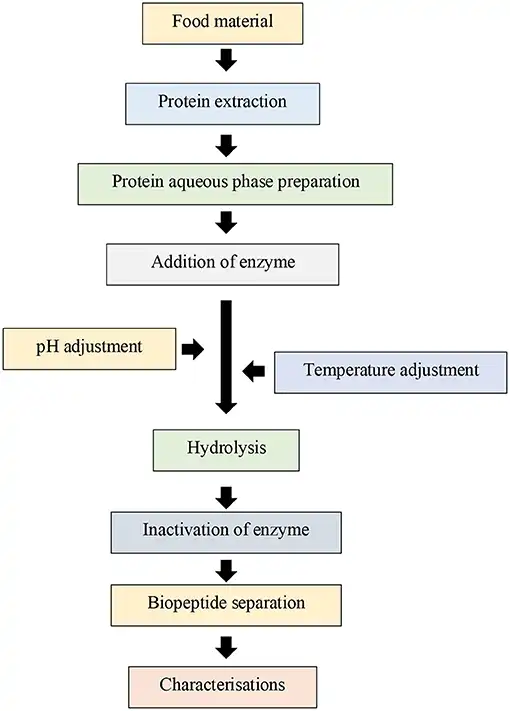

Corn Protein Extraction

The production of hydrolyzed corn protein powder begins with the extraction of protein from corn kernels. This involves separating the protein-rich components from other parts of the corn, such as starch and fiber. Advanced milling and separation techniques are employed to isolate the corn protein efficiently. The resulting protein concentrate serves as the starting material for the hydrolysis process.

Enzymatic Hydrolysis Process

Enzymatic hydrolysis is the core step in producing hydrolyzed corn protein powder. Specific enzymes, carefully selected for their ability to cleave peptide bonds, are introduced to the corn protein concentrate. These enzymes work under controlled conditions of temperature, pH, and time to break down the protein molecules into smaller peptides and free amino acids. This step is crucial in determining the final properties of the hydrolyzed protein, including its molecular weight distribution and functional characteristics.

Purification and Drying

After hydrolysis, the resulting mixture undergoes purification to remove any unwanted components and standardize the product. This may involve filtration, centrifugation, or other separation techniques. The purified hydrolysate is then carefully dried, typically using spray-drying technology, to produce a fine, easily dispersible powder. The drying process is optimized to preserve the nutritional and functional properties of the hydrolyzed corn protein.

Functional Roles in Flavor Enhancement and Texture Improvement

Umami Flavor Enhancement

Hydrolyzed corn protein powder is renowned for its ability to impart umami flavor to food products. The hydrolysis process releases free glutamic acid and other flavor-enhancing amino acids, which contribute to a rich, savory taste. This umami effect can elevate the overall flavor profile of various food products, making them more palatable and satisfying to consumers. Food manufacturers often use hydrolyzed corn protein to enhance the taste of soups, sauces, and savory snacks without relying on artificial flavor enhancers.

Mouthfeel and Texture Modification

Beyond flavor enhancement, hydrolyzed corn protein powder plays a significant role in improving the texture and mouthfeel of food products. The smaller peptides and amino acids resulting from hydrolysis can interact with other food components, contributing to a smoother, more cohesive texture. In meat products, for example, hydrolyzed corn protein can enhance juiciness and tenderness. In plant-based alternatives, it can help mimic the textural properties of meat, improving consumer acceptance of these products.

Emulsification and Stability

The functional properties of hydrolyzed corn protein extend to its emulsification capabilities. The peptides in hydrolyzed corn protein can act as emulsifiers, helping to stabilize oil-in-water emulsions in various food systems. This property is particularly valuable in sauces, dressings, and processed meat products, where it helps maintain product stability and prevent separation during storage. Additionally, the emulsification properties can contribute to a creamier mouthfeel in certain applications.

Usage in Plant-Based, Gluten-Free, and Processed Food Products

Plant-Based Meat Alternatives

The plant-based food market has seen remarkable growth, and hydrolyzed corn protein powder has emerged as a key ingredient in this sector. It serves multiple functions in plant-based meat alternatives, contributing to both flavor and texture. The umami-enhancing properties of hydrolyzed corn protein help create a more meat-like taste, while its ability to bind water and improve texture contributes to a more authentic mouthfeel. Manufacturers of plant-based burgers, sausages, and other meat analogues often incorporate hydrolyzed corn protein to achieve products that closely mimic the sensory experience of traditional meat products.

Gluten-Free Formulations

In the growing market for gluten-free products, hydrolyzed corn protein powder, also known as corn peptide, offers valuable functionality. It can help improve the texture and mouthfeel of gluten-free baked goods, which often struggle to achieve the desirable characteristics typically provided by gluten. The protein's water-binding properties can enhance moisture retention in gluten-free breads and pastries, leading to improved freshness and shelf life. Additionally, the flavor-enhancing capabilities of hydrolyzed corn protein can compensate for the sometimes bland taste of gluten-free products, making them more appealing to consumers.

Processed and Convenience Foods

The versatility of hydrolyzed corn protein powder makes it a valuable ingredient in a wide range of processed and convenience foods. In snack products, it can contribute to flavor complexity and improve texture. In ready-to-eat meals, soups, and sauces, it serves as both a flavor enhancer and a texturizer. The protein's ability to bind water can help maintain the desired consistency in these products during storage and reheating. Furthermore, its use in processed meats can enhance juiciness and flavor while potentially allowing for reduced sodium content, aligning with consumer demands for healthier options.

Conclusion

Hydrolyzed corn protein powder has become an indispensable ingredient in the food industry, offering a unique combination of flavor enhancement, texture improvement, and functional benefits. Its versatility allows for application across a wide range of food products, from plant-based alternatives to gluten-free formulations and processed foods. As consumer demand for clean-label, plant-based, and enhanced nutritional products continues to grow, hydrolyzed corn protein powder is poised to play an increasingly important role in food manufacturing. Its ability to address multiple formulation challenges while aligning with consumer preferences makes it a valuable tool for food product developers and manufacturers alike.

Contact Us

Are you interested in exploring how hydrolyzed corn protein powder can enhance your food products? Contact Shaanxi Bolin Biotechnology Co., Ltd. for high-quality, innovative plant-based solutions. Reach out to us at sales1@bovlin.com to discuss your specific needs and discover how our expertise can benefit your products.